Diagnomatic Software

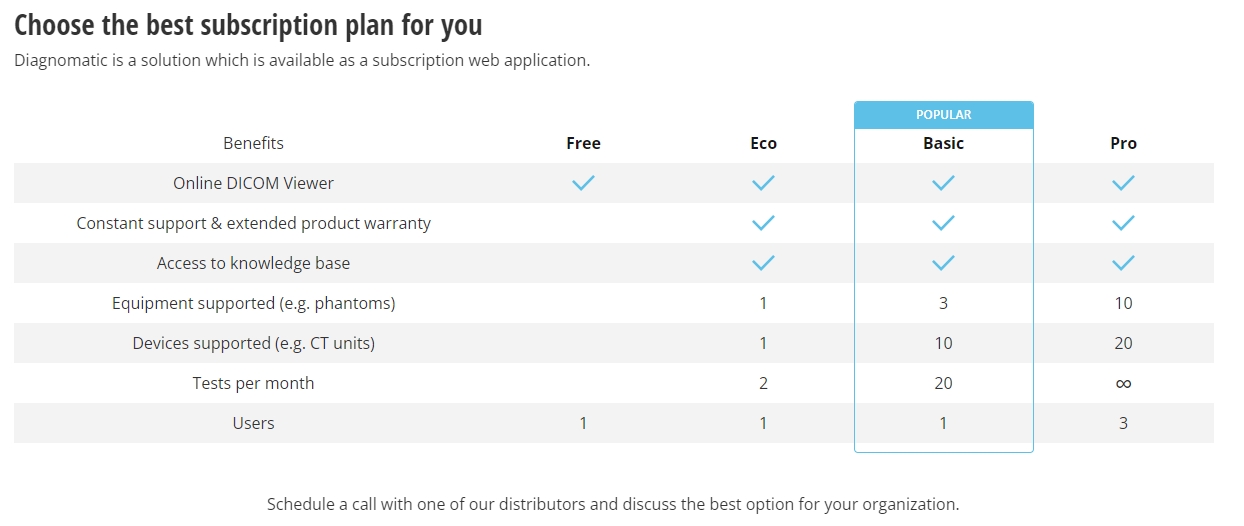

With more than 15 years of experience in healthcare imaging quality assurance, we designed DIAGNOMATIC a hardware and software solution which simplifies the process using automatic, certified, and cloud-based data analysis.

| Brand |

|---|

Automate Quality Tests.

Protect Patient Care.

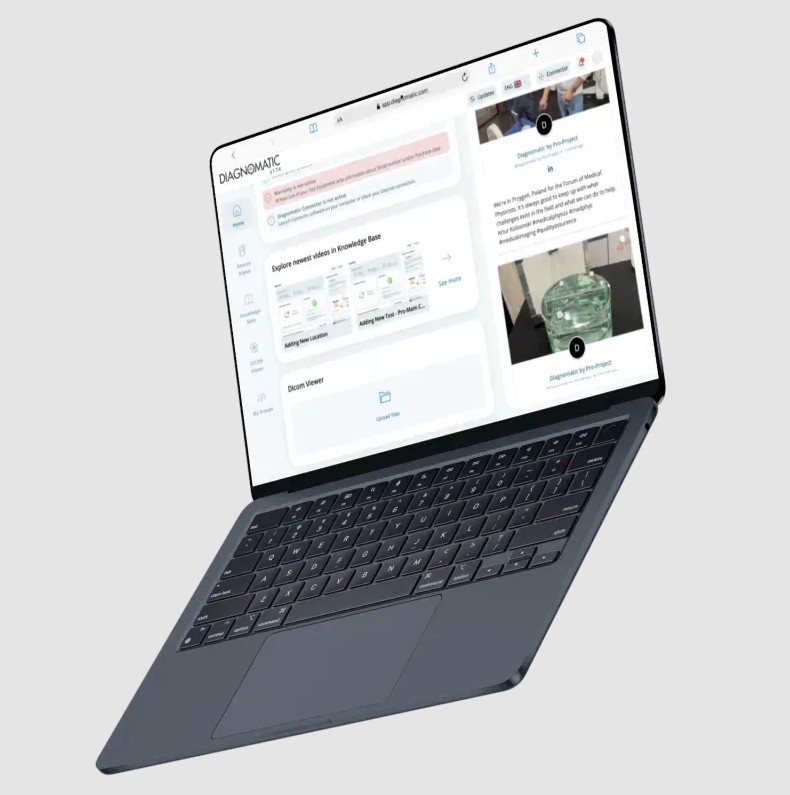

Diagnomatic’s intelligent software automates the testing process through automatic image scoring, detects issues early, guarantees image quality, and ensures equipment compliance, saving time, reducing errors, and strengthening diagnostic confidence.

- Supports multi-modality imaging (e.g., CT, MRI, mammography, etc.)

- Speeds up accreditation and audit readiness

- Facilitates team collaboration and test traceability

- Scalable for single sites or enterprise-wide deployments

- Instant alerts for missed or failed tests

- Automated documentation and audit-ready reports

- Flexible deployment: secure cloud access or on-premise installation

How it works?

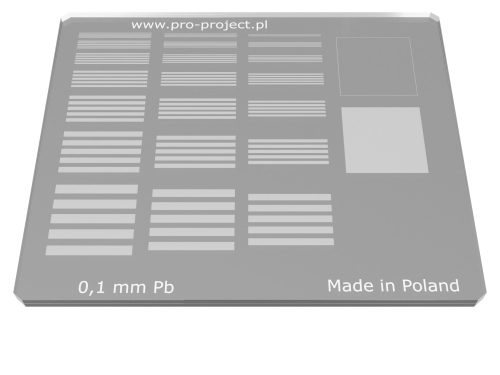

1. Scan The Phantom

You can use our „Many in one” phantoms for each modality so you can perform many tests at a single exposure or scan.

2. Send The Images

Send images to Diagnomatic Connector with DICOM protocol. Encrypted data form the Diagnomatic Connector are sent to the secure cloud.

3. Fast, Accurate Analysis

Images are automatically analyzed in the Diagnomatic secure cloud environment. The results are added to your account.

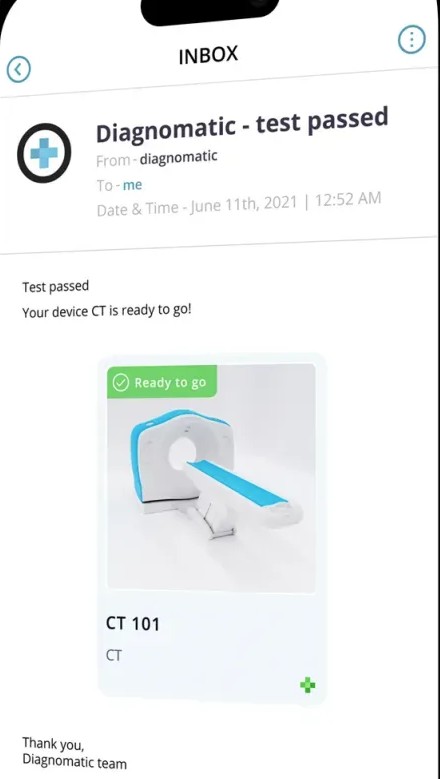

4. The Result

You will get an email confirming the device status. If anything needs your attention, you can open the app to check the details.

Features

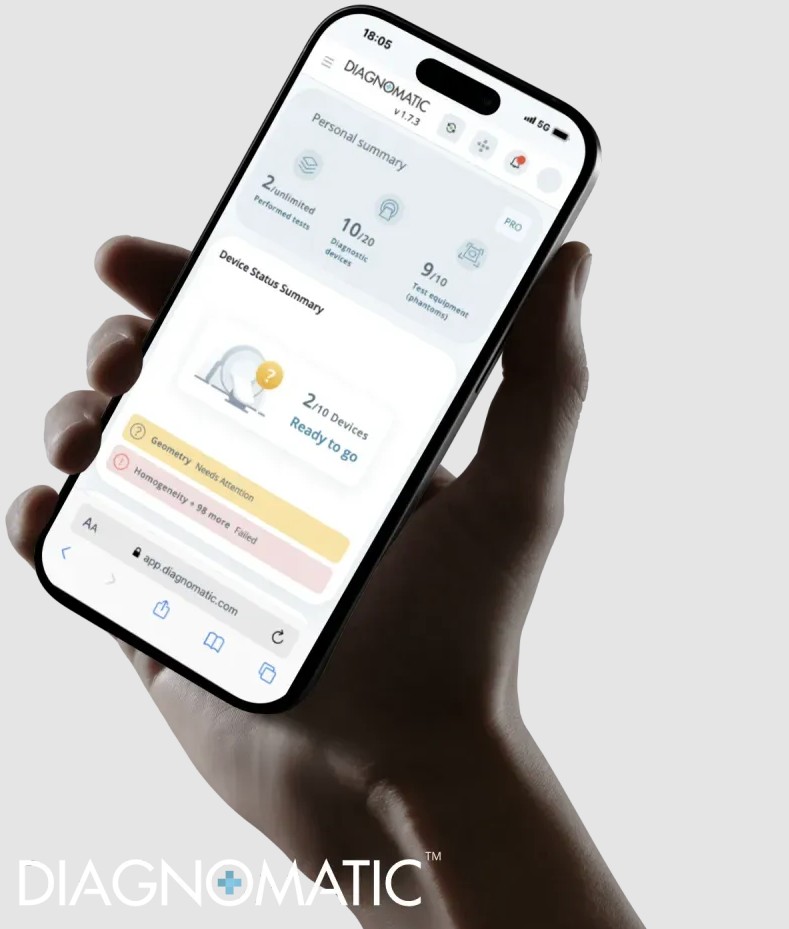

- Instant device status indicators and alerts

- Simplified quality control process with workflow automation

- Easy integration with the existing IT infrastructure

- Ability to manage an unlimited number of medical devices in any number of locations

- Standardized high-quality device data gathered in the secured cloud

- Access to data for you team from any device

- Multi-language support

- ISO 27001 certification

Automated image scoring and quality checks

- Ensures consistent, objective QA across all imaging systems.

Instant device status indicators and alerts

- Enables early issue detection and faster response times.

Workflow automation for simplified QA processes

- Reduces manual work, errors, and time spent on routine testing.

Support for unlimited devices and multiple locations

- Scalable for single-site facilities or enterprise-wide deployments.

Secure cloud-based data storage and access

- Standardized, high-quality QA data accessible anytime, anywhere.

ISO 27001-certified for data protection

- Compliant with international standards for information security.

Flexible deployment: cloud or on-premise

- Easily integrates with your existing IT infrastructure and security policies.

Multi-language support

- Ideal for international teams and global vendors.

Benefits

Hospital Management / Medical Service Providers

- Reduce the risk of misdiagnosis

- Cost reduction – less downtime, repetition and time needed for QA, more time for services

- Reduce the risk caused by malfunctioning imaging devices

- Make sure that all devices are in a top condition

- Lower total cost of ownership by constant automated device status monitoring

- Educate your staff on how quality and safety should be guaranteed

Medical Professionals

- Instant device status checks – clear readiness indicator

- Peace of mind – superior diagnosis reliability and radiation safety

- Time reduction – simplified and automated workflows

- Quality assurance – low risk of human errors

- Time management – reminders, alerts, timeliness

- Holistic understanding of the device health / condition

- Objective – Eliminate human error with images analysed by the software

- Ease of use – Simple and clear interface makes the software intuitive and quick to learn

- Optimised efficiency– the speed of the results means more regular testing can be done to ensure the device is healthy

Medical Imaging Device Manufacturers

- Time reduction – simplified and automated quality control workflow

- Holistic understanding of the device health / condition

- Predictive analytics – identification of malfunctions before they occur

- Competitive differentiation – quality assurance of top devices

- A large amount of quality data for research and development

- Provide your staff with safety and quality education to better support your clients