Interlocking Lead Bricks

The Interlocking Lead Bricks V-shaped edges allow safe and easy stacking to form a walled enclosure, minimizing the chance of collapsing.

| Brand |

|---|

The flat surface of rectangular lead brick gives good protection. But for maximum protection, we offer interlocking chevron bricks.

Their V-shaped edges allow safe and easy stacking to form a walled enclosure, thus minimizing the chance of collapsing.

InMed Healthcare offers several sizes and thicknesses as well as end and corner brick to meet your particular requirements.

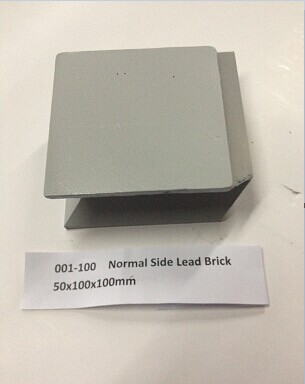

Standard interlocking lead brick: 10.1cm x 10.1cm x 5cm thick (L x H)

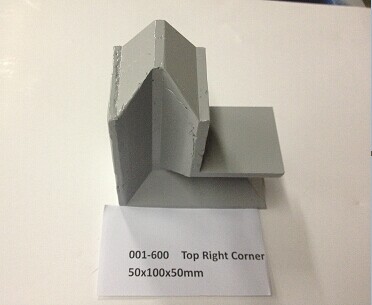

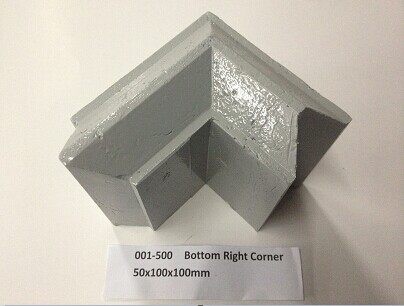

Corner interlocking lead bricks: 10.1cm x 10.1cm x 5cm Thick (L x H)

Top Cap interlocking bricks: 10.cm x 5cm x 5cm thick (L x H)

Features

-

Interlocking Design: The interlocking feature of these lead bricks eliminates any radiation leakage between the bricks, ensuring a secure and stable shielding structure.

-

Customization Options: Choose between raw lead finish or a protective coating. Painted bricks are typically used to create a shielded enclosure for a working area, while raw lead bricks are used to construct radiation-shielded walls.

-

High Radiation Attenuation: Lead’s density (11.34 g/cm³) and high atomic number (82) make it particularly effective at blocking X-rays and gamma rays, ensuring maximum protection in medical, industrial, and research environments.

-

Versatile Applications: Ideal for constructing temporary or permanent radiation shields, storage areas, and protective barriers in facilities such as hospitals, laboratories, nuclear plants, and research institutions.

-

Modular Design: Can be customized in size, thickness, and shape to meet specific shielding requirements.

-

Easy Installation and Adaptation: Lead bricks can be installed between structural elements like studs or steel tubing, allowing for the integration of conduits and cabling without compromising radiation protection.